Protecting Composite Materials from UV Damage

Table Of Contents

Innovative Technologies in UV Protection

Recent advancements have led to the development of various innovative technologies designed specifically to enhance UV protection for composite materials. These technologies encompass a range of solutions, from advanced coatings to the integration of nanoparticles, aimed at increasing resistance to UV degradation. Coatings that utilise UV-stabilising compounds can significantly prolong the life of composites, making them suitable for prolonged outdoor use. Additionally, the incorporation of UV-absorbing materials at the manufacturing stage offers another layer of defence against harmful radiation.

Research into self-healing polymers has introduced a cutting-edge approach to maintaining the integrity of composite materials. When exposed to sunlight, these materials can repair minor UV-induced damage autonomously, thus extending their functional lifespan. Furthermore, the development of reflective coatings that minimise heat absorption also plays a critical role in protecting composites from the adverse effects of UV rays. By embracing these innovative technologies, industries can enhance the durability and performance of their composite products, ensuring they withstand the rigours of environmental exposure.

Advancements in Composite Material Treatments

Recent years have witnessed significant progress in the treatments available for composite materials, particularly regarding their resistance to ultraviolet (UV) radiation. Innovative coatings and additives have been developed to enhance the durability of these materials. Advanced formulations now include UV stabilisers that absorb harmful rays, significantly reducing the degradation that typically occurs over time. By integrating nanoparticles into composite structures, manufacturers can further improve UV resistance, ensuring that the mechanical properties of the materials remain intact for longer periods.

In addition to surface treatments, there has been a surge in research focused on developing inherently UV-resistant composite materials. This approach involves modifying the chemical structure of the resins used in the composites. The aim is to create materials that do not merely rely on external coatings for protection but possess built-in resilience against UV exposure. Such advancements allow for more versatile applications and extend the lifespan of composites used in outdoor environments, where UV exposure can be especially detrimental.

Choosing the Right Material

Selecting materials that naturally possess UV resistance is crucial for applications requiring durability against sunlight exposure. Some composites utilise additives that enhance their resistance, while others may be formulated specifically for outdoor usage. Knowing the specific application can guide the choice of material, as not all composites perform equally well under prolonged UV exposure.

Understanding the environment in which the composite will be used also plays a pivotal role in making the right selection. Factors such as geographic location, altitude, and typical weather patterns influence how materials respond to UV radiation. Evaluation of these external conditions helps ensure that the chosen composite can withstand the rigours of its intended application, ultimately extending its lifespan and maintaining its performance.

Factors to Consider for UV Resistance

When selecting composite materials for applications exposed to UV radiation, the choice of resin is paramount. Different resins exhibit varying levels of resistance to UV degradation. Epoxy and vinyl ester resins tend to offer better UV stability compared to polyester resins. Additionally, incorporating UV stabilisers during the manufacturing process can significantly enhance the longevity of composites by absorbing or reflecting harmful UV rays. This consideration is particularly vital for outdoor structures or products that remain under constant sunlight exposure.

Another critical factor involves the composite's colour and surface finish. While lighter colours generally reflect UV radiation more effectively than darker shades, finishes can also influence degradation rates. Smooth, glossy finishes often provide an added layer of protection by reducing the surface area that sunlight can penetrate. Regular maintenance and coatings can further prolong the lifespan of composites by creating a barrier against UV damage, making proactive care essential for sustaining performance over time.

Environmental Considerations

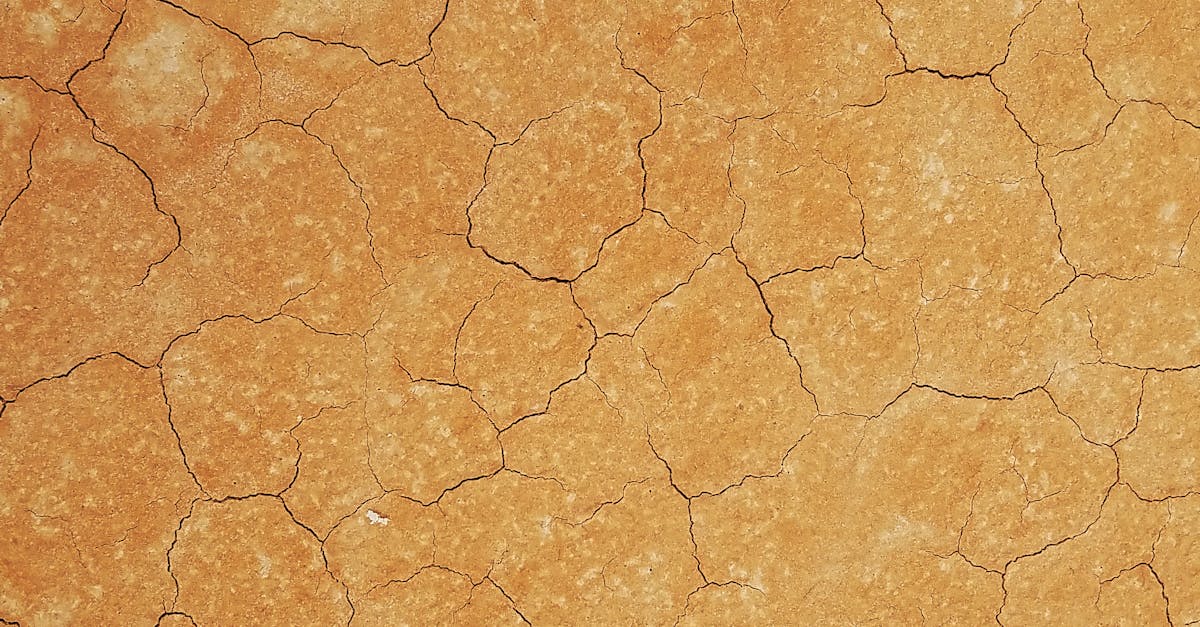

The longevity of composite materials is significantly influenced by environmental conditions. High levels of UV radiation can be detrimental, particularly in regions with a warm climate and minimal cloud coverage. Rain and humidity can also contribute to the degradation of these materials, elevating the risk of water ingress that may lead to further structural damage. Understanding the local climate helps in selecting appropriate composites designed to withstand specific environmental stresses.

Different climates pose unique challenges for composite materials. For instance, coastal areas with salty air can accelerate corrosion, while extreme temperature fluctuations can induce expansion and contraction, leading to cracks. Sustainability considerations are also important; composites designed for harsh environments often require more energy-intensive production and disposal processes, which can negate their ecological benefits. Taking these factors into account is crucial in ensuring the long-term performance and sustainability of composite materials.

How Climate Affects Composite Longevity

Climate plays a critical role in the longevity of composite materials. Variations in temperature, humidity, and exposure to UV radiation can accelerate wear and degradation. Regions with high UV exposure lead to more rapid breakdown of surface resins, reducing the material's overall integrity. Conversely, areas with excessive moisture can promote mould growth and corrosion, which further deteriorate composites over time.

The geographical location and prevailing weather patterns significantly influence the maintenance strategies required for composite materials. In coastal environments, saltwater and humidity increase the risk of chemical decomposition and physical damage. Implementing appropriate protective coatings or regular maintenance schedules can help mitigate these effects. Understanding local climate conditions is essential for selecting the right materials and ensuring their longevity in specific applications.

FAQS

What are composite materials and why are they used?

Composite materials are made from two or more constituent materials that, when combined, produce a material with different properties to each individual component. They are commonly used for their high strength-to-weight ratio, durability, and versatility in various applications, including construction, automotive, and aerospace industries.

How does UV radiation damage composite materials?

UV radiation can break down the chemical bonds in composite materials, leading to degradation. This can result in loss of strength, discolouration, and a reduction in overall durability, making the materials more susceptible to environmental stresses.

What innovative technologies are available for UV protection of composites?

Innovations for UV protection include the development of UV-absorbing additives, coatings that reflect UV rays, and treatments that enhance the inherent UV resistance of the matrix resin used in composite materials.

What factors should I consider when choosing a composite material for UV resistance?

Key factors to consider include the type of resin used, the presence of UV stabilisers or absorbers, the material's intended use environment, and the expected exposure duration to sunlight. Additionally, it is important to assess the material's overall durability and maintenance requirements.

How does climate impact the longevity of composite materials?

Climate can significantly affect the performance of composite materials. High temperatures and humidity can accelerate degradation, while extreme UV exposure in sunny climates can lead to quicker deterioration. Proper selection of materials and protective treatments can help mitigate these effects and enhance longevity.

Related Links

Common Mistakes to Avoid When Caring for Composite MaterialsPreventing and Treating Mildew on Composite Surfaces

Ensuring Longevity: Maintenance Schedules for Composite Wall Cladding

The Role of Sealants in Maintaining Composite Cladding

Understanding the Lifespan of Composite Wall Cladding

Seasonal Maintenance Checklist for Composite Wall Cladding